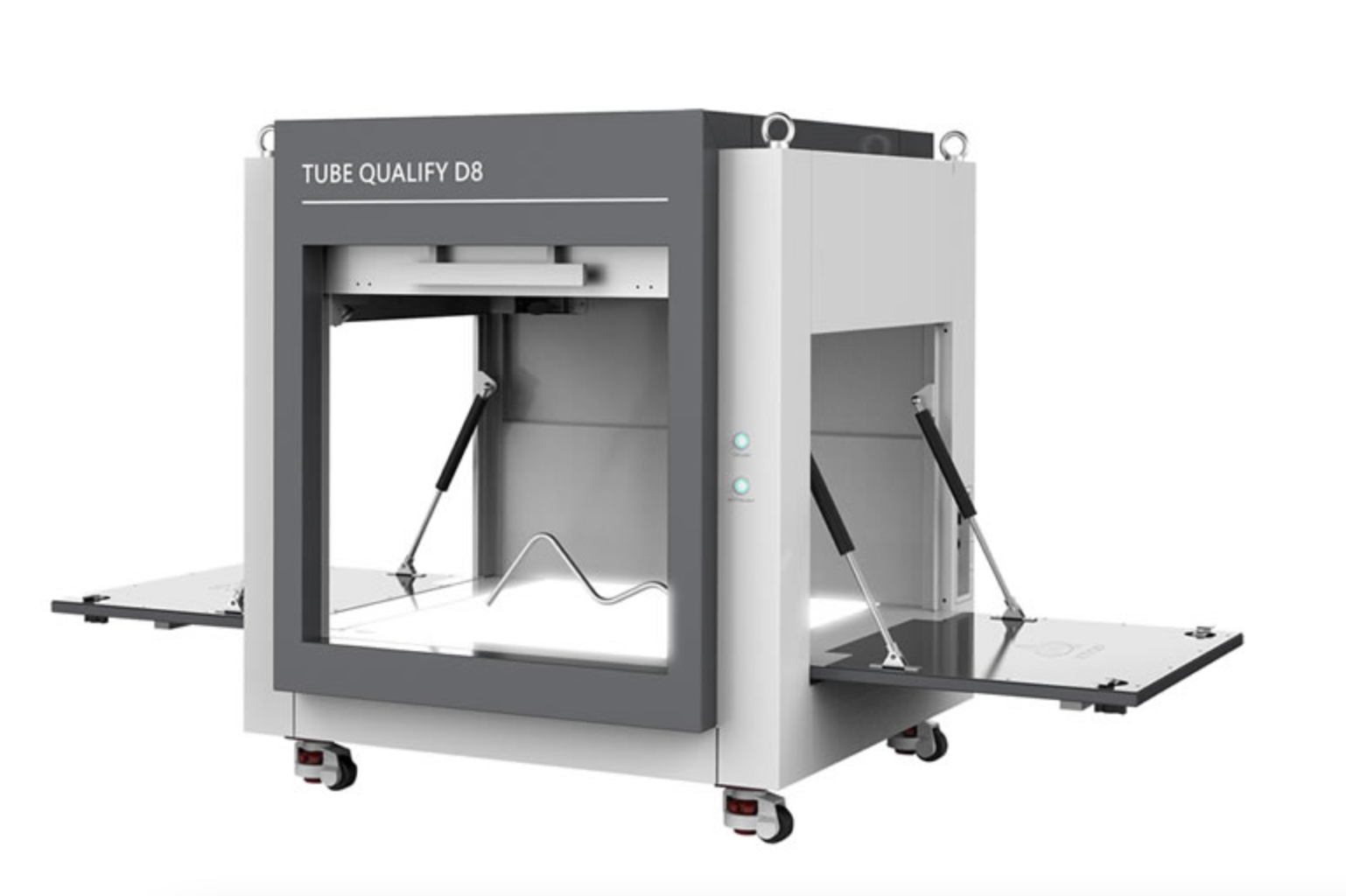

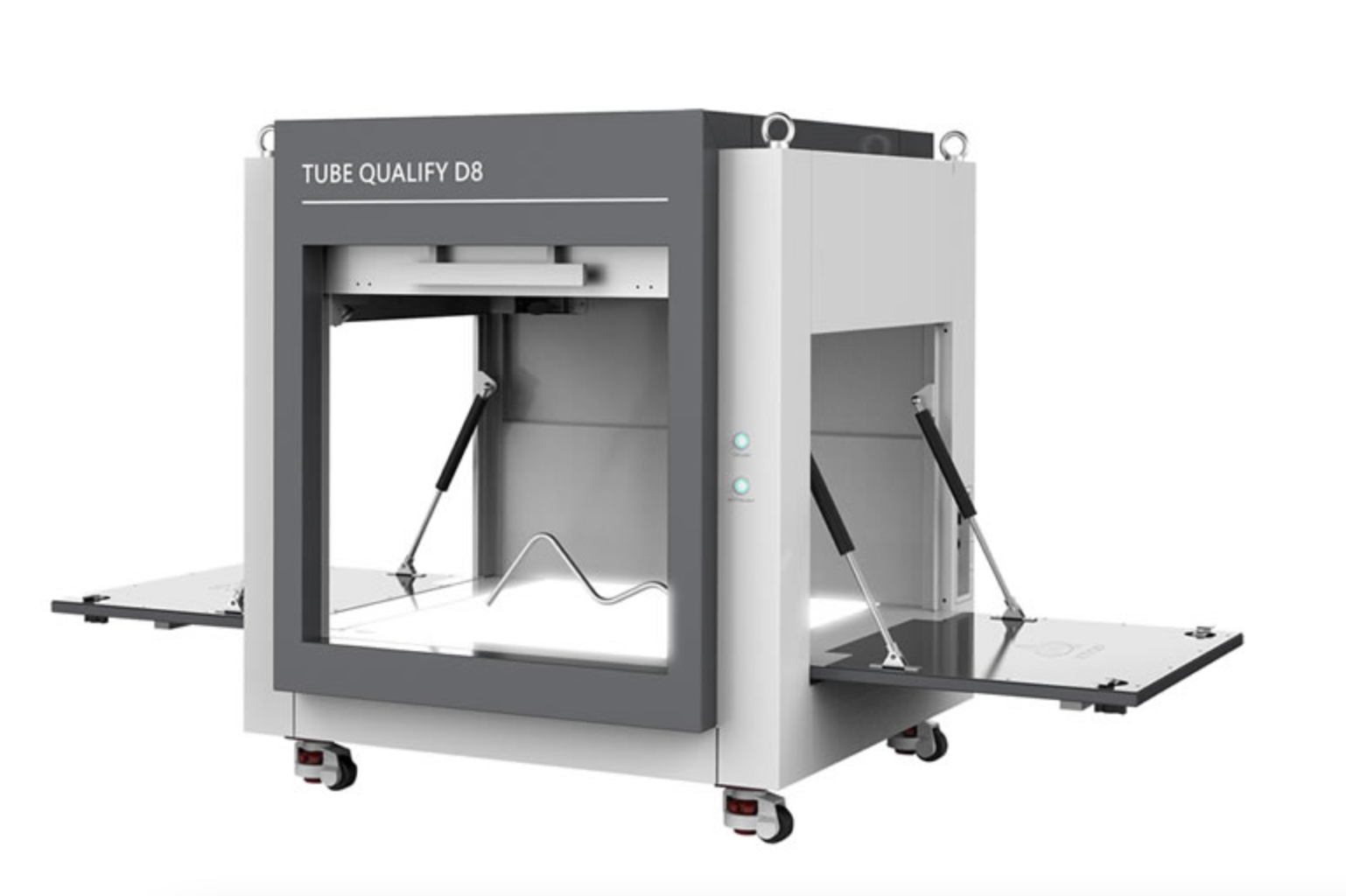

quality multiple bending tube parts 3D scanner inspection systems

2021-03-22

Tube processing instruction——to provide guidance for the correction of tube bender

Since tube parts are easy to spring back and deform during processing, it is necessary to repeatedly try to confirm tube bender parameters. After the tube processing is completed, the Tube Qualify system is used for online inspection, and the inspection results are automatically sent to the CNC tube bender. By comparing the theoretical and measured values, Tube Qualify can provide the output of the tube correction amount, be used to adjust and optimize the tube processing, which ensures the quality of tube parts. In any case, MH Tube Qualify 3D optical tube measurement system can calibrate the tube bender faster, which saves production time and reduces unnecessary material waste. At the same time, machine settings become predictable, and downtime is greatly reduced.

More details or you have any questions?

We would be more than happy to help you.

WhatsApp/Wechat: +86-182 9141 8396 Email: lemon@mh-elec.com

tel

tel