| Tube Qualify 3D Optical Bending Tube Measurement System |

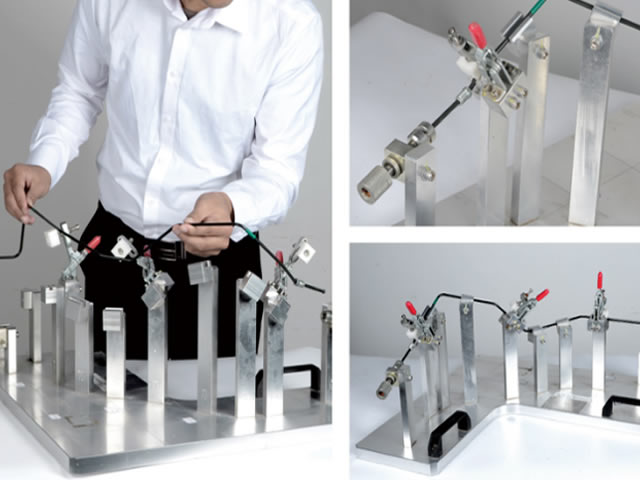

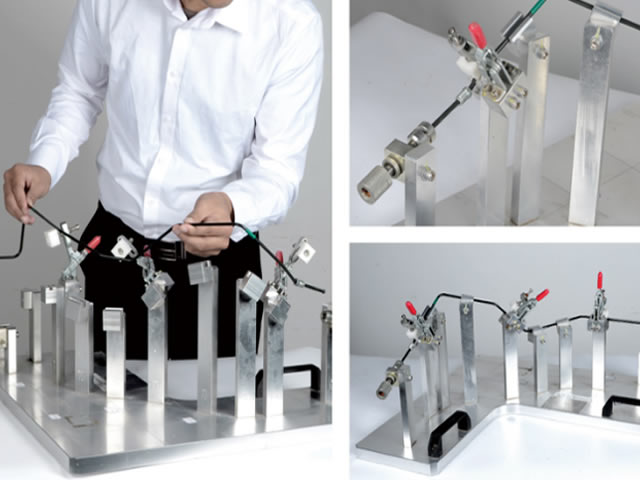

Tube Qualify is a 3D optical bending tube measurement system. It canquickly reconstruct 3D digital model of the bending tube in 2 secondsand complete the measurement of multiple bending tubes at one time.The system can be applied to on-line inspection of bending tube instead of manual inspection, which solves the problem that a large number ofinspection fixtures need to be saved. The system has high flexibility andcan be customized according to the user's use scenario.

Application Advantages

● High Precision Industrial Camera;

● LED lighting, long life and low maintenance cost, provides stable lighting for online inspection;

● Strong environmental adaptability, good stability, it can be used immedia tely without re-calibration after changing the location;

● Side door can be used as support platform to increase measurable size;

● One machine can replaces a large number of traditional inspection fixtures to reduces the production cost of customers;

● It is suitable for mass inspection in industrial production and can inspectmultiple bending tubes at one time;

Provide customers with the best solution

All functions of Tube Qualify software are developed and designed aroundthe design and production process of bending tube, each production anddesign process requires different types of data.

Widely used in measurement and production processes

From design to process planning, to production and manufacturing, andfinally to the whole process of bending tube quality inspection, Tube Qualifycan provide efficient solutions.

1、Tube Qualify-D8 Technical Data

|

Model

|

Tube Qualify-D8

|

|

camera resolution

|

1.3M

|

|

Number of cameras

|

8

|

|

Measurement range (mm)

|

600*400

|

|

Measurement accuracy (mm)

|

0.2

|

|

Applicative tube diameter(mm)

|

3-100

|

|

Calibration board

|

400mmx400mm

|

|

Computer

|

IPC

|

|

Overall dimension (mm)

|

800x600x1000

|

|

Equipment weight (KG)

|

50

|

2、Tube Qualify-X10 Technical Data

|

Model

|

Tube Qualify-X10

|

|

camera resolution

|

2M

|

|

Number of cameras

|

10

|

|

Measurement range (mm)

|

1300*600

|

|

Measurement accuracy (mm)

|

0.05

|

|

Applicative tube diameter(mm)

|

3-200

|

|

Calibration board

|

600mmx600mm

|

|

Computer

|

DELL Precision T3420

|

|

Overall dimension (mm)

|

1500x900x2100

|

|

Equipment weight (KG)

|

450

|

3、Tube Qualify-X16 Technical Data

|

Model

|

Tube Qualify-X16

|

|

camera resolution

|

2M

|

|

Number of cameras

|

16

|

|

Measurement range (mm)

|

2600*1250

|

|

Measurement accuracy (mm)

|

0.1

|

|

Applicative tube diameter(mm)

|

3-2200

|

|

Calibration board

|

1000mmx1000mm

|

|

Computer

|

DELL Precision T5820

|

|

Overall dimension (mm) (mm)

|

2700x1500x1500

|

|

Equipment weight (KG)

|

1500

|

Request A quick Quote (WhatsApp:+ 86-18792456795)

tel

tel