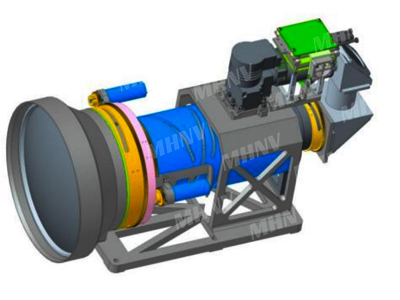

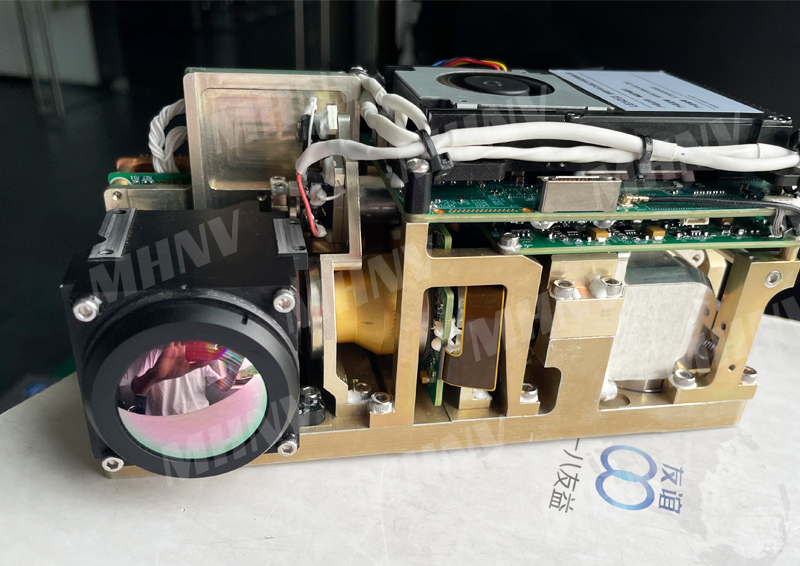

1280*1024/640*512 Cooled Thermal Core with 50-1100mm Continuous Zoom

VIDEO

MH MW-50- 1100 thermal imager (hereinafter referred to as " MW-5--100 ") is integrated in various typ es of photoelectric systems. It is mainly used to complete infrared detection, identification, recognition and reconnaissance, int elligence gathering, targeting, etc. of targets at night or under bad weather conditions.

1 Requirements for functions and main technical indicators

1.1 Features

1) Manual focusing, which ca n read the current focal length value and provide a focal length value.

2) Manual zoom, can read the zoom value, and can provide the zoom value.

3) Automatic focusing.

4) Black hot/white hot polarity conv ersion.

5) Manually and automatically adjust brightness and contrast.

6) Bad pixel replacement.

7) NUC.

8) Adjustment of integration time.

9) Digital zoom: 2x, 4x.

1.2 Requirements for main technical indicators

1) Detector

Table 1 Detector indicators

Item

indicators

Response band

3μm ~ 5μm( nominal value )

Array specifications

1280×1024

Pixel size

15μm

NETD

NETD ≤25 mk ( @25℃ )

F- number

5.5

Bad pixel rate

≤0.5%

Focal plane operating temperature

≤82K ( design guarantee )

2) Optical system indicators

a) Electric continuous zoom lens. Focal length: 50~ 1100mm.

b) F- number : 5.5

c) The parallelism between the optical axis and the installation base shall not

exceed 0.5mrad.

d) Minimum focal distortion ≤ 3% (design gua rantee).

3) Start time

The startup time of the entire machine is ≤ 9 minutes ( full temperature range ).

4) Continuous working hours

The continuous working time of the entire machine shall not be less than 10 hours.

2 Size and weight

1) Overall dimensions ≤500mm×235mm×290mm ( L×W×H ) . ( Please refer to the attachment for details )

2) Weight : ≤11.0kg 。

3 Electrical interfaces and protocols

1) Power supply voltage: DC stabilized power supply 24V ± 2V, working curre nt not exceeding 1.5A.

2) Analog video outp ut: 1 channel PAL analog video.

3) Digital video output: 1 CameraLink, digital progressive scanning, frame rate ≥ 25 frames/second.

4) Communication interface and protocol: see Annex 1 for details.

5) Electrical interface definition: see Annex 2 for details.

4 Environmental adaptability

1) Operate temperature : -40℃ ~ +60℃ ;

2) Storage temperature : -45℃ ~ +70℃ ;

3) Vibration and shock: sh ock waveform: half sine wave; The duration of 15G is 3 times in each direction of the vertical, vertical, and horizontal axes (11ms ± 2ms).

5 Packaging require ments

Safety protection transport box.

Annex 1

Appendix Table 1 Data Format Sent by Upper Computer to Thermal Imager

Communication protocol : RS 422, full duplex .

Communication format : 1 bit start bit , 8 bits data bit , 1 bit stop bit , no parity check

Baud rate : 38400b/s

No

Command

Description

1

Sync Header 1

0 xEB

2

Sync Header 2

0x90

3

Command

See Appendix Table 2 for details

4

Backup (0)

Zoom lens position , 8 bit low

5

Backup (1)

Zoom lens position, 8bit high

6

Backup (2)

0x00

7

Backup (3)

0x00

8

Checksum

3-7 byte checksum

Appendix Table 2 Oper ation Command

No

Command

Description

Code

1

IR Focus +

Focal position adjustm ent

0x83

2

IR Focus -

Focal position adjustm ent

0x84

3

Auto Focus

Auto Focus

0x61

4

IR Large FOV

Increase field of view

0x85

5

IR Small FOV

Reduce field of view

0x86

6

IR Positive/Negative P olarity Switch

Backup [0]=0 ( Cyclic switching polarity )

Backup [0]=1 ( White hot )

Backup [0]=2 ( Black hot )

0x87

7

IR Integral Time +

Increase integration time

0x88

8

IR Integral Time -

Reduced integration ti me

0x89

9

Correction

Non-uniformity correction

0x8A

10

E- zoom 2x , 4x

Backup [0]=0 ( cyclic switching

electronic zoom coe fficient)

Backup [0]=1 (1 x electronic zoom )

Backup [0]=2 (2 x electronic zoom )

Backup [0]=4 (4 x electronic zoom )

0x8B

11

IR Brightness and Contrast Manual Adjust

Manual adjustment of bright ness and contrast

0x8C

12

IR Brightness and Contrast Auto Adjust

Automatic adjustment of brightn ess and contrast

0x8D

13

IR Brightness +

Brightness increase

0x8E

14

IR Brightness -

Brightness reduction

0x8F

15

IR Contrast +

Contrast increase

0x90

16

IR Contrast -

Contrast reduction

0x91

17

IR Edge Sharpen +

Edge enhancement increase

0x63

18

IR Edge Sharpen -

Edge enhancement reduction

0x65

19

IR Output Self-check Image

When the thermal imager receives 0x94,

the device outputs a self inspecti on

image; When the thermal imager

receives other control commands, the

device outputs a normal image.

0x94

20

Blind Filling

Blind Filling

0x02

21

Manual Blind Filling

Manual Blind Filling

0x20

22

Saving Data

Saving Data

0x21( Send 2 times in 10S)

23

Cross on/off

Cross on/off

0x22

24

Cross H +

Cross H +

0x23

25

Cross H -

Cross H -

0x24

26

Cross V +

Cross V +

0x25

27

Cross V -

Cross V -

0x26

28

Reset Cross

Reset Cross

0x27

29

Background Correction

Background Correction

0x28

30

Lens Setting

Zoom position setti ng Backup [0] ( Low 8 bit ) Backup [1] ( High 8 bit )

0x29

31

Focus Setting

Focus position setting Backup [0] ( Low 8 bit ) Backup [1] ( High 8 bit )

0x2A

32

Image Flip

Backup [0]=0 ( loop switching ) Backup [0]=1 ( normal image ) Backup [0]=2 ( Image flipping )

0x2B

Appendix Table 3 Da ta Format for Sending Thermal Imager to Upper Computer

No

Command

Description

1

Sync Header 1

0 xEB

2

Sync Header 2

0x90

3

IR Lens Value

Zoom lens position , 8 bit low

4

IR Lens Value

Zoom lens position , 8 bit high

5

Status Bit

Status bit, See Appendix Table 4 for details

6

IR Focus Value

Focus lens position , 8 bit low

7

IR Focus Value

Focus lens position , 8 bit high

8

Checksum

3-7 byte checksum

Appendix Table 4 Status Bit

Bit No .

Description

D7

IR Status

=0 Normal ; = 1 Fault

D6

Image Status

=0 Normal Image ; = 1 Test Image

D5

Cooler Fault

=0 Normal ; = 1 Fault

D4

Imager Self-check Status =0 Normal ; = 1 Fault

D3

Communication Status of Serial Port that receive in-done master co ntrol =0 Normal

= 1 Fault

D2

Temp Alarm =0 Normal = 1 Fault

D1

XX

D0

XX

Annex 2

Thermal imager extern al connector model: J30V2-25TJ -L1. One set o f

corresponding connectors should be provided for the enti re machine.

Appendix Table 5 Definition of External Connectors f or Thermal Imagers

Pin No .

Definition

Requirement

1 、 2 、 12

VIN 24V

Twisted-pair

3 、 4 、 13

GND 24V

5

GND 3.3 V RS 422

6

RX 0+

Twisted-pair

7

RX 0-

8

TX 0+

Twisted-pair

9

TX 0-

10

PAL_GND

11

PAL

14

GND CAM

15

GND CAM

16

CLK +

Twisted-pair

17

CLK -

18

X3+

Twisted-pair

19

X3-

20

X2+

Twisted-pair

21

X2-

22

X1+

Twisted-pair

23

X1-

24

X0+

Twisted-pair

25

X0-

Different lens available:

Request A quick Quote (WhatsApp:+ 86-18792456795)

tel

tel