187 9245 6795

Email: mh_elec@126.com or jacky@mh-elec.com

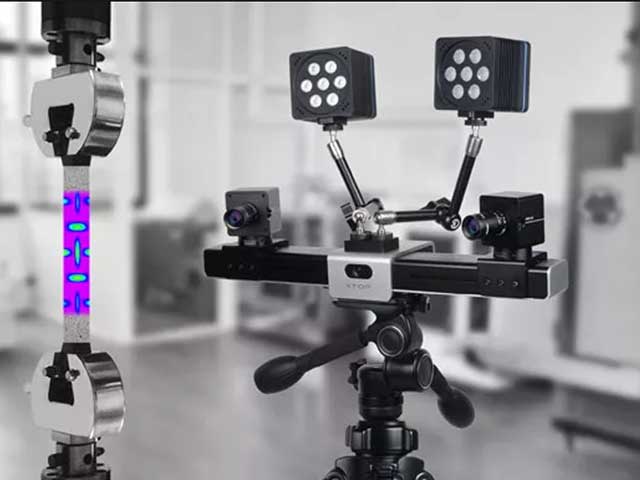

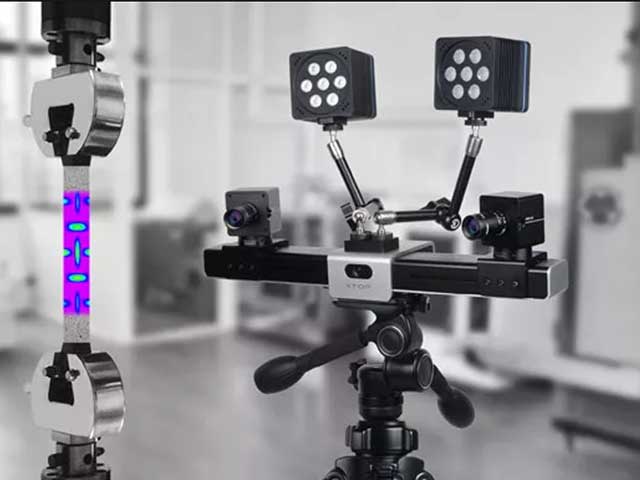

MHDIC system combines digital image correlation technology(DIC) and binocular stereo vision technology to realize the measurement of 3D coordinates, displacement field and strain field of the object surface in the process of deformation by tracking the speckle image of the object surface. It combines with binocular stereo microscopy technology to realize the measurement of 3D coordinates, displacement field and strain field of the surface of small object in the process of deformation.

Real-time measurement, real-time calculation and real-time output

Full-field strain calculation and result display can be carried out in real time rather than post-processing; while collecting images, 3D full-field strain calculation can be carried out in real time, with online and offline computing processing modes, supporting the real-time output of the calculated results in UDP and other ways.

The system configuration is flexible to support customized development

Supports multiple camera interfaces such as millions to tens of millions of pixels, low-speed to high-speed, gigabit network, USB 3.0 and camera Link, CXP, etc. the system software control module can support online synchronous acquisition frame rate up to 4500 fps (non-high-speed acquisition, storage, download and then import mode).

Multiple extended interfaces

With universal testing machine interface, it can collect realtime force and displacement signals of the testing machine; with cupping machine interface, it can measure FLC curve of materials; with microscope interface, it can realize 3D full-field deformation and strain kdetection of several millimeter or even smaller objects; with multi camera synchronous measurement, it can measure deformation and strain of multiple areas simultaneously. Mutli-channel A/D input, multi-channel D/A output, multi-channel switching input and output, and flexible expansion.

|

Model

|

CONST-SD

|

CONST-HR

|

CONST-HS

|

|

Camera resolution

|

2.3 ~ 5M

|

up to 25 M

|

up to 4 M

|

|

Camera frame rate

|

75fps-160fps

|

30fps-42 fps

|

up to millions of fps

|

|

Strain measurement accuracy

|

50με

|

20με

|

50με

|

|

Strain measurement range

|

0.005 ~ 2000%

|

|

Displacement measurement accuracy

|

≤0.01pixel

|

|

Measurement range

|

m㎡ ~ 10m x 10m

|

|

Real time computation

|

support

|

/

|

|

Multi-probe synchronous measurement

|

support

|

|

Control system

|

standard model

|

high speed model

|

|

Material of calibration board

|

aluminium alloy

|

|

Typical configuration

|

1920x1200@160fps, 2448x2048@75fps

|

4096x2168@42fps, 4096x3000@30fps

|

2336x1728@560fps, 2048x1536@8500fps, 1920x1080@12742fps

|

Engineer Manager Name: Jacky

WhatsApp/ Wechat: 0086-187 9245 6795

Email: mh_elec@126.com or jacky@mh-elec.com

tel

tel