| MH-M Blue Light 3D Scanning System |

Engineer Manager Name: Jacky

WhatsApp/ Wechat: 0086-187 9245 6795

Email: mh_elec@126.com or jacky@mh-elec.com

MH-M is a high precision optical measurement system, developed and manufactured specially for industrial 3D digital inspection, it's suitable for full-scale 3D digital inspection of geometric shape of the object to be measured. Blue light 3D scanning system has industrial-grade high precision and high stability, it's able to provide high-precision measurements in harsh environments.

|

Model

|

M-1.3M

|

M-3M

|

M-5M

|

M-9M

|

|

Camera resolution

|

1.31M

|

3M

|

5m

|

9m

|

|

Measurement accuracy(mm)

|

0.02/0.03

|

0.015/0.02

|

0.008/0.01

|

0.005/0.008

|

|

Scan space

|

single image<1S

|

single image<2S

|

|

Point space (mm)

|

0.15/0.3

|

0.1/0.2

|

0.08/0.16

|

0.06/0.12

|

|

Measurement range (mm)

|

200x150/400x300

|

|

Projection light source

|

Blue light multifrequence phase shift

|

|

Scanning mode

|

Non-contact measurement

|

|

Splicing mode

|

|

Global splicing of landmarks,automaticsplicing of single-axis or multi-axis turntable

|

|

Precision control

|

|

Automatic monitoring;built-in global error control;global positioning control of photogrammrtry

|

|

Probe weight (kg)

|

|

2.4

|

|

System support

|

|

Win7 / Win10 64-bit

|

Industrial level probe

MH-M blue light 3D scanning system adopts an integrated shell design, which effectively protects the precision parts such as industrial cameras and industrial lenses inside the probe. All electronic components are purchased and manufactured at highest technological level. Even in various harsh operating environments, the measurement accuracy and stability of the system can be guaranteed. The appearance design of the equipment conforms to ergonomics, and the scanning head band handle design is convenient to operate.

Automatic Splicing

MH-M blue light 3D scanning system supports a variety of automatic splicing method, such as global splicing of marking points, featuring splicing, single-axis or multi-axis turntable automatic splicing and other splicing methods, to ensure the accuracy of data splicing and measurement efficiency.

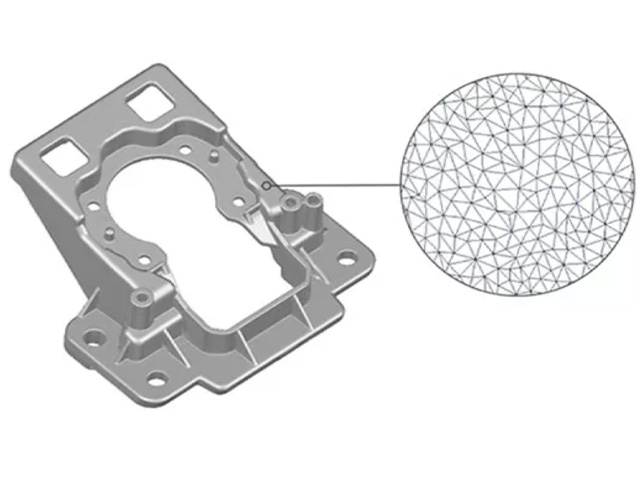

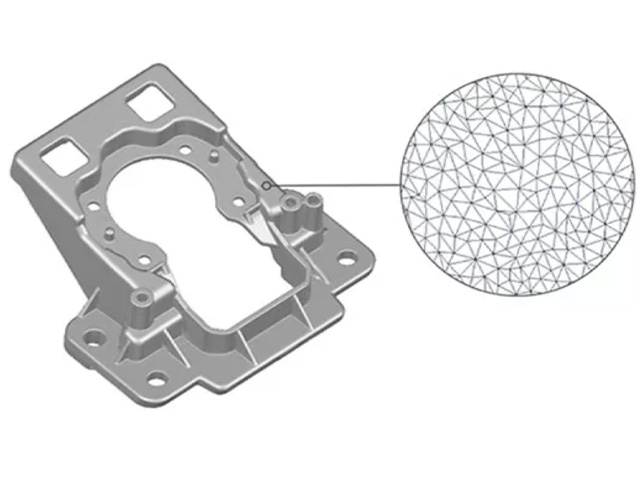

High Precision and High Pixel Grid date

MH-M blue light 3D scanning system can obtain the global distribution of 3D point cloud data and high precision grid data in each measurement. The resolution of the camera can reach 9 million and higher pixels, and the measurement data can show very high resolution of ultra-fine details, so it is also suitable for 3D measurement of micro parts.

Calibration is convenient and fast

MH-M blue light 3D scanning system is calibrated with certified calibrator. The whole calibration process has operation instructions, which is convenient and fast, improves user efficiency and ensures measurement accuracy. When used with turntable, the system can automatically calibrate.

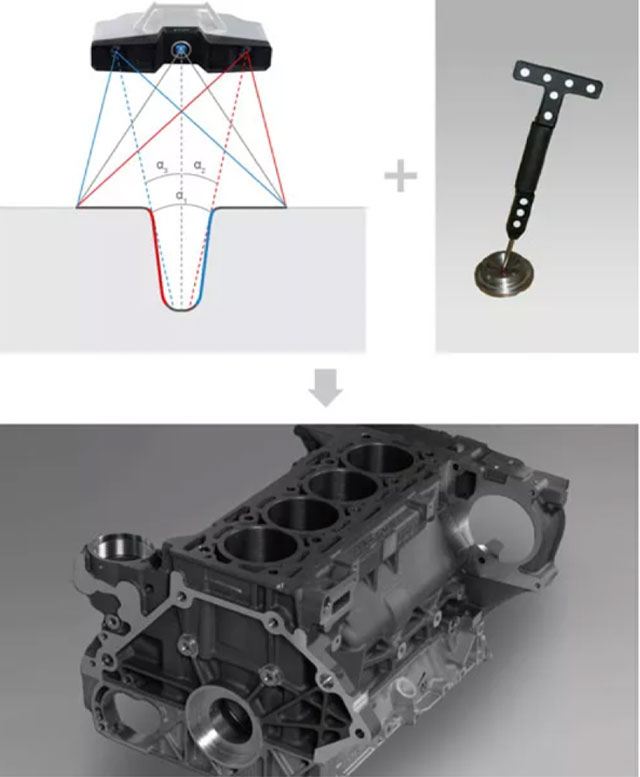

Applied to complex parts shape

Even for complex parts, it can easily get complete 3D data information of work piece. Such as: deep grooves, fine edges, complex parts and so on.

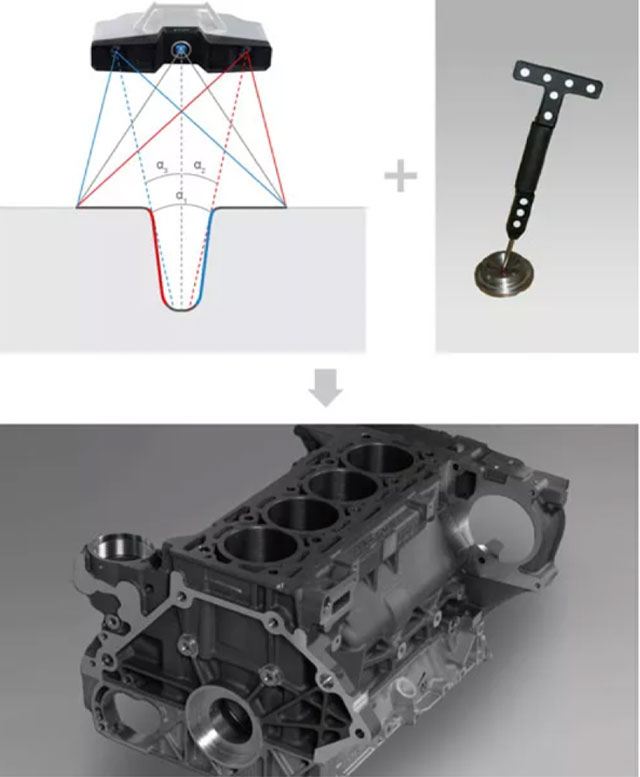

Used in conjunction with 3D photogrammetry

When measuring large and complex parts, the accuracy of global measurement and splicing can be effectively improved by using XTDP 3D optical photogrammetry system. The accuracy can reach +0.015mm/m

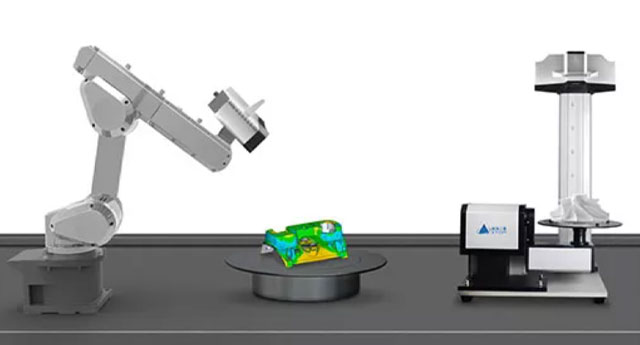

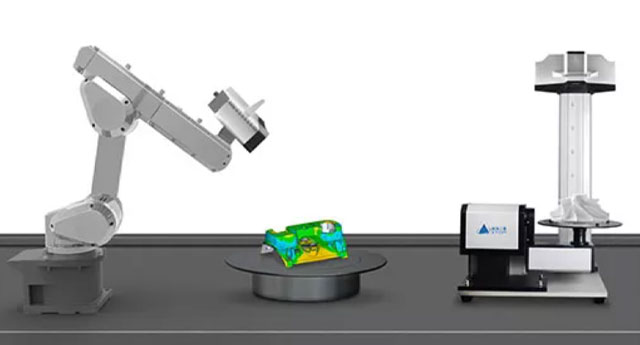

Automation Application

MH-M can be equipped with different types automatic turntable and automatic joint arm, which can be used for automatic measurement and inspection of components, quality control in production and manufacturing process, or batch automatic measurement of multiple components.

Engineer Manager Name: Jacky

WhatsApp/ Wechat: 0086-187 9245 6795

Email: mh_elec@126.com or jacky@mh-elec.com

Request A quick Quote (WhatsApp:+ 86-18792456795)

tel

tel