| MHDIC-CONST DIC 3D Full-Field StrainMeasurement and Analysis System |

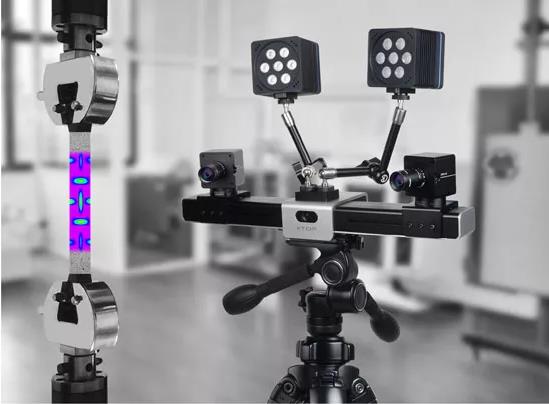

MHDIC system combines digital image

correlation technology(DIC)and binocular stereo vision

technology to realize the measurementof 3D coordinates, displacement

field and strain field of the objectsurface in the process of

deformation by tracking the speckleimage of the object surface.

It combines with binocular stereo microscopy technology to realize the measurement of 3D coordinates, displacement field and strain field of the surface of small object inthe process of deformation.

Technical Advantages

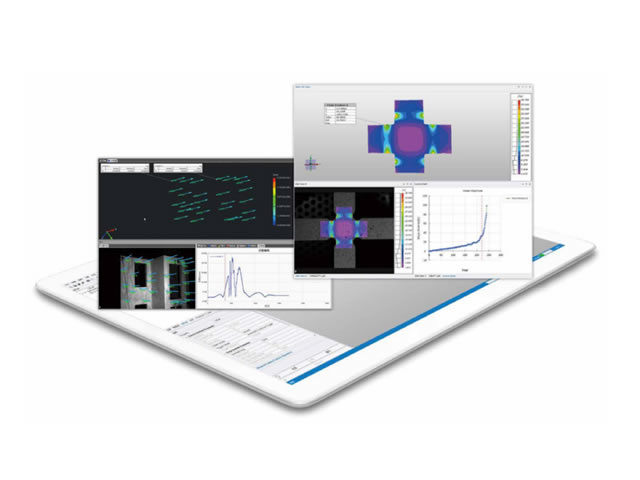

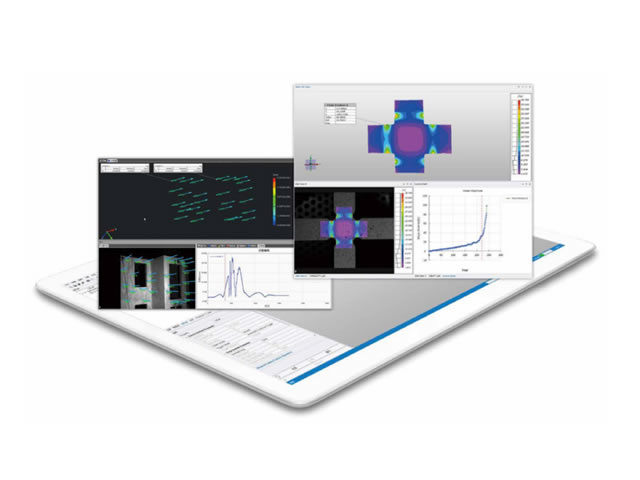

Real-time measurement, real-time calculation and real-time outputFull-field strain calculation and result display can be carried out in realtime rather than post-processing; while collecting images, 3D full-fieldstrain calculation can be carried out in real time, with online and offlinecomputing processing modes, supporting the real-time output of thecalculated results in UDP and other ways.

Advanced system technology

It is the first self-developed digital image correlation method 3D dimensional deformation measurement system in China, and the corealgorithm ofindependent intellectual property rights, technical indicators have reached the international advanced level.

The system configuration is flexible to support customized development

Supports multiple camera interfaces such as millions to tens of millions ofpixels, low-speed to high-speed, gigabit network, USB 3.0 and cameraLink,CXP, etc. the system software control module can support online synchronous acquisition frame rate up to 4500 fps (non-high-speed acquisition, storage, download and then import mode).

High compatibility

It is compatible with two-dimensional measurement of single camera and 3D multiprobe measurement of multicamera.

Multiple extended interfaces

With universal testing machine interface, it can collect realtime forceand displacement signals of the testing machine; with cuppingmachineinterface, it can measure FLC curve of materials; with microscopeinterface, it can realize 3D full-field deformation and strain kdetectionof several millimeter or even smaller objects; with multicamera synchronous measurement, it can measure deformation and strain ofmultiple areas simultaneously. Mutli-channel A/D input, multi-channelD/A output, multi-channel switching input and output, and flexible

XTDIC-CONST-SD Technical Data

|

ModelMH

|

DIC-CONST-SD

|

|

Camera resolution

|

2.3~5 M

|

|

Camera frame rate

|

75fps~160fps

|

|

Strain measurement accuracy

|

50με

|

|

Strain measurement range

|

0.005 ~ 2000%

|

|

Displacement measurement accuracy

|

≤0.01pixel

|

|

Measurement range

|

mm² ~ 10m×10m

|

|

Real time computation

|

support

|

|

Multi-probe synchronous measurement

|

support

|

|

Control system

|

standard model

|

|

Material of calibration board

|

aluminium alloy

|

|

Typical configuration

|

1920×1200@160fps、2448×2048@75fps

|

XTDIC-CONST-HR Technical Data

|

ModelMH

|

DIC-CONST-HR

|

|

Camera resolution

|

up to 25 M

|

|

Camera frame rate

|

30fps~42 fps

|

|

Strain measurement accuracy

|

20με

|

|

Strain measurement range

|

0.005 ~ 2000%

|

|

Displacement measurement accuracy

|

≤0.01 pixel

|

|

Measurement range

|

mm² ~10m×10m

|

|

Real time computation

|

support

|

|

Multi-probe synchronous measurement

|

support

|

|

Control system

|

standard model

|

|

Material of calibration board

|

aluminium alloy

|

|

Typical configuration

|

4096×2168@42fps、4096×3000@30fps

|

XTDIC-CONST-HS Technical Data

|

Model

|

MHDIC-CONST-HS

|

|

Camera resolution

|

up to 4 M

|

|

Camera frame rate

|

up to millions of fps

|

|

Strain measurement accuracy

|

50με

|

|

Strain measurement range

|

0.005 ~ 2000%

|

|

Displacement measurement accuracy

|

≤0.01pixel

|

|

Measurement range

|

mm² ~ 10m×10m

|

|

Real time computation

|

/

|

|

Multi-probe synchronous measurement

|

support

|

|

Control system

|

high speed model

|

|

Material of calibration board

|

aluminium alloy

|

|

Typical configuration

|

2336×1728@560fps、2048×1536@8500fps、1920×1080@12742fps

|

Request A quick Quote (WhatsApp:+ 86-18792456795)

tel

tel