| 3D Full-Field Strain Measurement |

MHDIC Three-dimensional Digital Image Correlation Full-Field Strain Measurement

Digital Image Correlation (DIC) is a 3D, full-field,

non-contact optical technique to measure contour, deformation, vibration and

strain on almost any material. The technique can be used for many tests

including tensile, torsion, bending and combined loading for both static and

dynamics applications. The method can be applied from very small (micro) to

large testing areas – and the results are readily comparable with FEA results

or strain gauges.

Fields of Application

1)Materials

testing(Yang's modulus, Poisson's ratio, elastic-plastic performance

parameters)

2)Components

and parts testing(displacement measurement, strain measurement)

3)Biomechanics

(bones, muscles, blood vessels, etc.)

4)Analysis

of morphology and strain(micron-scale, nanometer-scale)

5)Fracture

Mechanics

6)Verification

of Finite Element Analysis (FEA)

7)High-speed

deformation measurement(dynamic measurement, instantaneous measurement)

8)Dynamic

strain measurement, such as fatigue test

9)Real-time

measurement of the FLC-curve

Technical Features

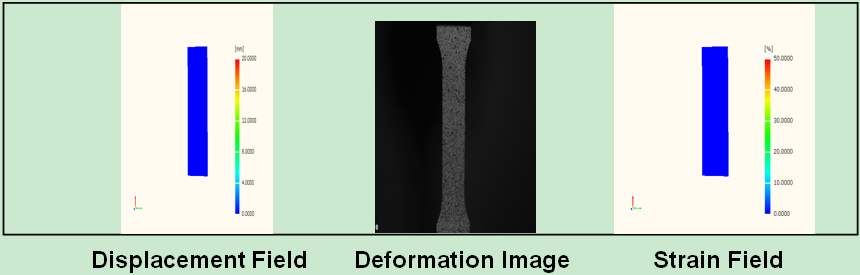

1)Non-contact

dynamic measurement. Obtaining the full-field three-dimensional coordinates,

displacement, and strain data.

2)Multi-mode

3D display of the measurement results

3)Suitable

for any material

4)Fast,

simple and high-precision calibration

5)Measurement

format: from 4mm to 4m

6)Range

of strain measurement: from the minimum of 0.01% to the maximum greater than

1000%

7)Flexible

and easy trigger function; free adjustment of acquisition frequency

8)Multithreaded

computing; higher computing speed

9)32-bit

or 64-bit operating system

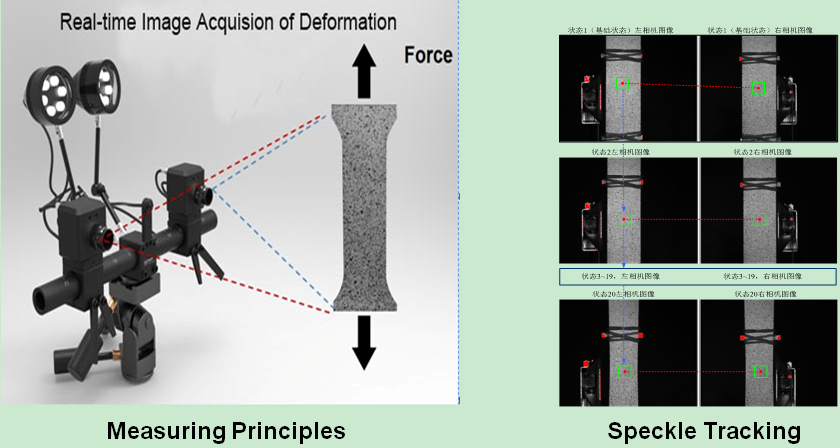

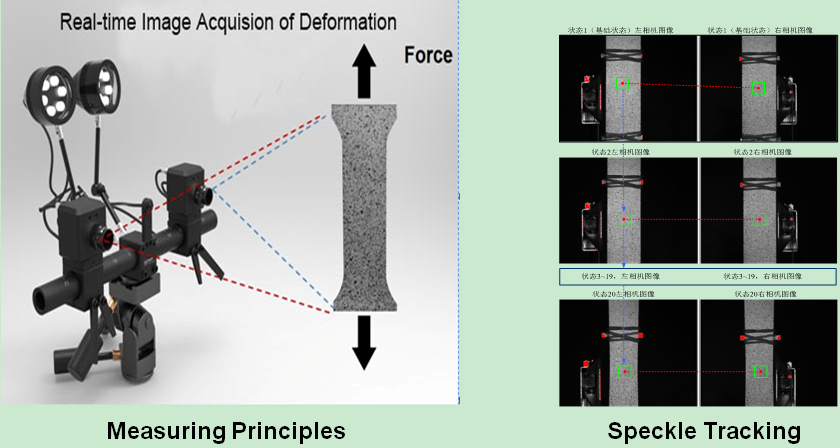

Principles of Measurement

Based on

Digital Image Correlation(DIC),

binocular stereo vision technology and industrial close range

photogrammetry, XTDIC offers a potable, high-speed, high-precision and simple

operation solution for three dimensional coordinates, displacement and strain

measurement during deformation by tracking the speckle patterns on the tested

object surface.

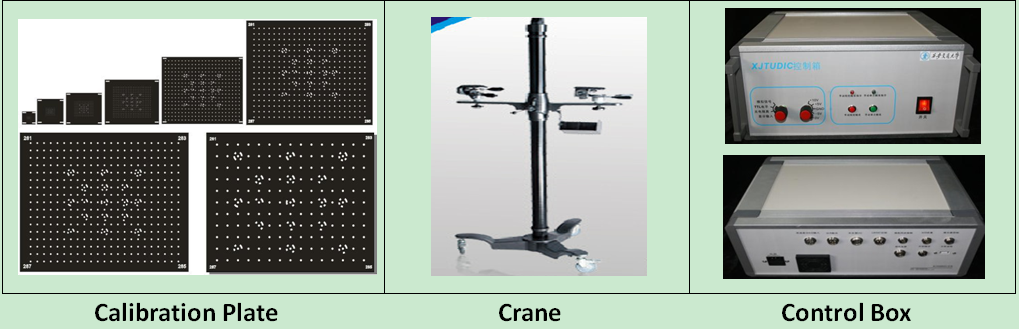

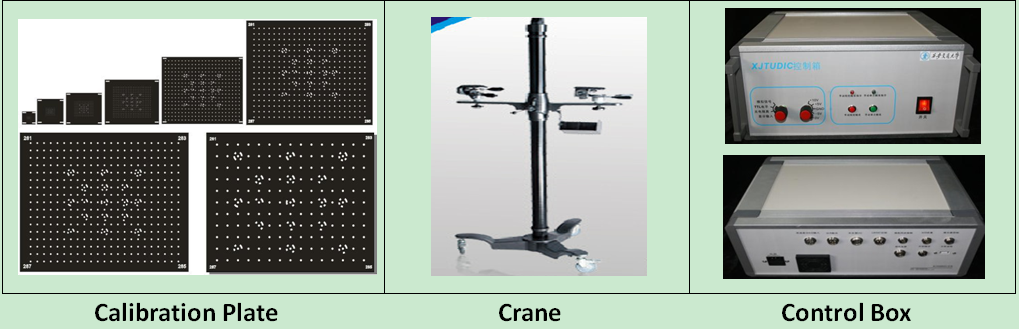

Easy to Operate

Based on

photogrammetric cameral calibration, XTDIC offers a fast, high-precision and

easy calibration solution for different measurement ranges of the formats.

Equipped with a crane, it is easy to operate. Various types of light sources

provide good illumination conditions for different environment measurement.

Multi-function control boxes provide a variety of A/D acquisition, D/A output

and trigger function, meeting coordinated operation of peripherals and loading

devices.

Software Functions

1)Support

two or three dimensional deformation measurement simultaneously

2)Flexible

camera calibration, supporting external image calibration

3)Providing

flexible and convenient parameter-setting for image acquisition, satisfying the

needs of image acquisition in different conditions

4)Flexibly

select the object range of interest, improving processing efficiency

5)Flexibly

set the size and step length of speckle to meet user requirements of different

accuracy and resolution

6)High

speed strain computing,providing eighteen different types of results of

deformation and strain

7)3D

display of calculating results, flexible 3D display

8)Multiple

post-processing functionalities, including filling holes by interpolation, data

smoothing, etc.

9)Coordinates conversion

10)Various

analysis of section line, single point and point pair

11)Curve

plotting

12)Report

form of measuring and analysis results

13)Synthetic

videos of measurement results, pictures and curves

Application Cases

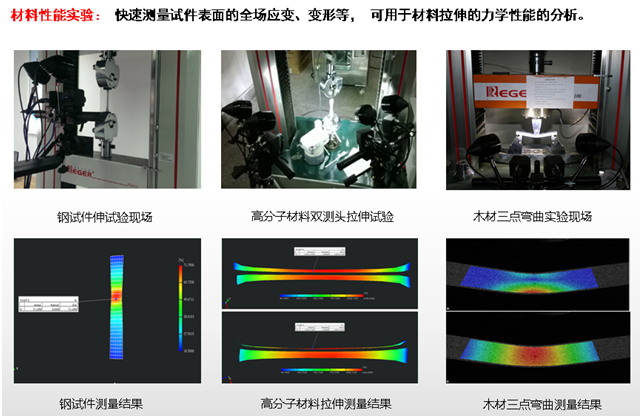

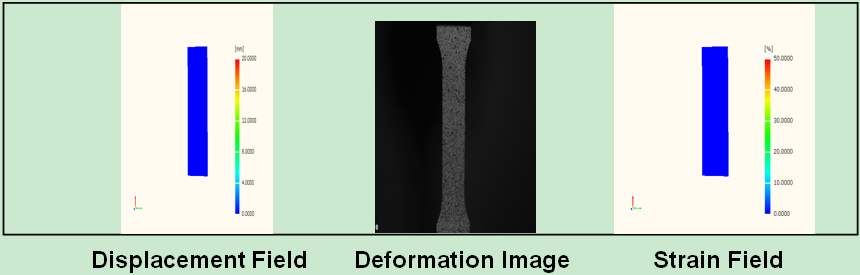

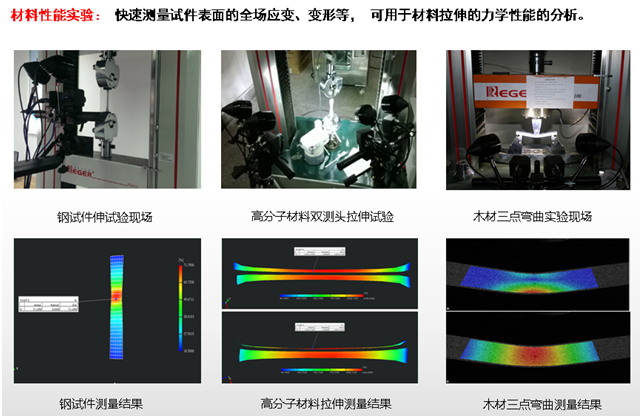

Material Performance Tests

FIG. Application Cases of

Material Performance Tests

Performance experiment of materials:

rapid measurement of the whole strain, deformation, etc. on the specimen

surface, and this can be used to analyze

the tensile mechanical properties of materials.

Test site of steel specimen tensile

Measurement result of the steel

specimen

Twin probe tensile test of the polymer

materials

Measurement result of polymer tensile

test

Test site of wood three-point bending

Measurement result of wood three-point

bending measurements

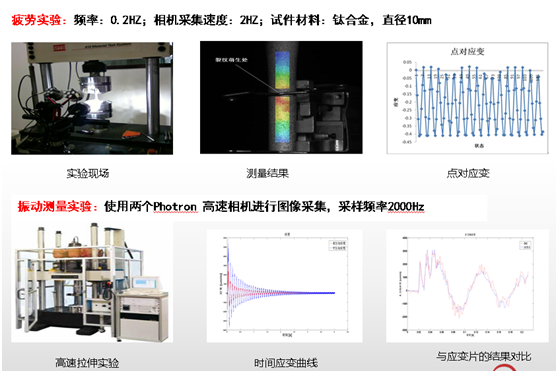

Dynamic Strain Measurement

FIG. Dynamic Strain

Measurement

Fatigue Test: Frequency: 0.2HZ; camera

capture speed: 2HZ; Test material: titanium, 10cm diameter

Experimental site

Measurement result

Strain point

Vibration Measurement Experiment:

Using two Photron high-speed camera for image acquisition, with the sampling

frequency being 2000Hz

High-speed tensile test

Strain curve

Comparison with the results of the

strain gauge

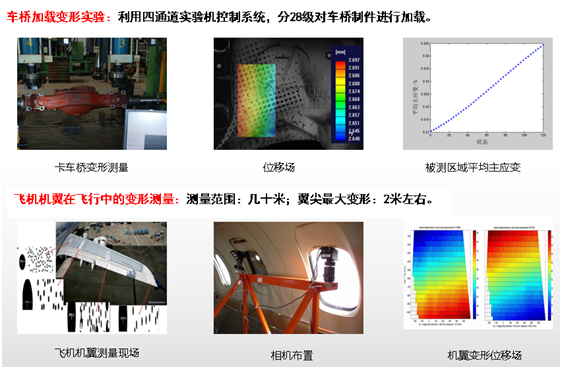

Deformation Measurement of Components

and Parts

FIG. Deformation Measurement of Components and

Parts

Axle load deformation experiment:

controlling the system by using four-channel test machine, loading the axle

parts with 28 levels.

Deformation measurement of the truck

bridge

Displacement field

Average principal strain of the

measured region

Deformation measurement of the

airplane wing in flight: Measuring range: tens of meters; maximum deformation

of wingtip: 2 meters.

Aircraft wing measuring site

Camera Setting

Wing deformation displacement field

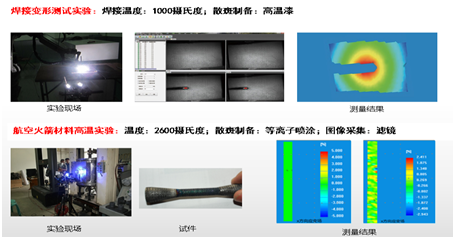

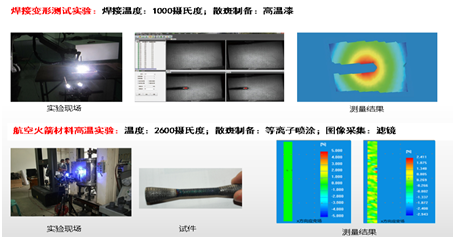

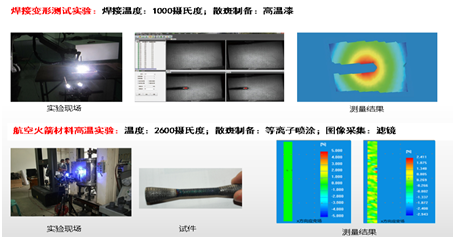

High-temperature Deformation

Measurement

FIG. Application Cases of High-temperature

deformation measurement

High-temperature Deformation

Measurement

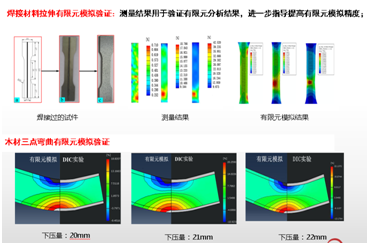

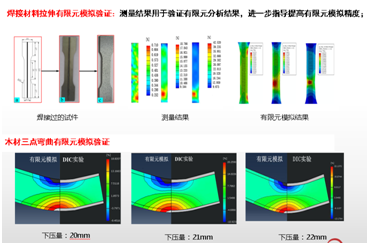

Verification

of Finite Element Analysis (FEA)

FIG. Verification of Finite

Element Analysis (FEA)

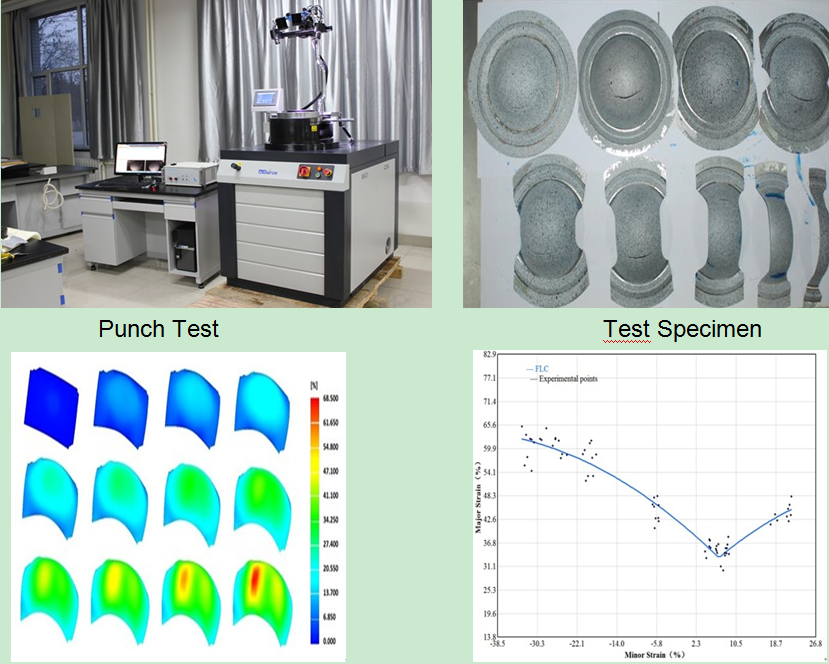

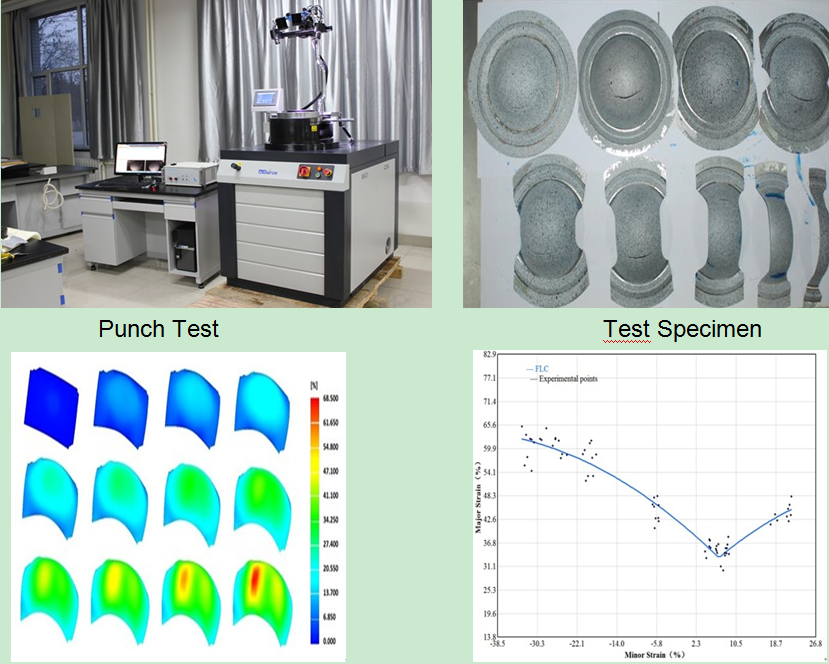

FLC Measurement

Forming Limit Curve (FLC) is used to

determine the degree of material deformation when in the state of stretching,

bulging, or combination of stretching and bulging. Combined with punch test

machine, XTDIC offers real-time dynamic measurement of forming limit curve for

sheet metal.

CONFIGURATION

AND TECHNICAL DATA

|

MODEL

|

XTDIC-SD(STANDARD)

|

XTDIC-HR-Ⅰ(HIGH RESOLUTION)

|

XTDIC-HR-Ⅱ(HIGH RESOLUTION)

|

|

CAMERA

RESOLUTION(PIXEL)

|

200 mega

|

410 mega

|

600 mega

|

|

FRAME RATE

|

20fps

|

25fps

|

13fps

|

|

STRAIN ACCURACY

|

0.005%

|

0.005%

|

0.005%

|

|

STRAIN RANGE

|

0.01%-1000%

|

0.01%-1000%

|

0.01%-1000%

|

|

MODEL

|

XTDIC-HS-Ⅰ(HIGH SPEED)

|

XTDIC- HS-Ⅱ(HIGH SPEED)

|

XTDIC- HS-Ⅲ(HIGH SPEED)

|

|

CAMERA

RESOLUTION(PIXEL)

|

410 mega

|

230 mega

|

200 mega

|

|

FRAME RATE

|

90fps

|

160fps

|

340fps

|

|

STRAIN ACCURACY

|

0.005%

|

0.005%

|

0.005%

|

|

STRAIN RANGE

|

0.01%-1000%

|

0.01%-1000%

|

0.01%-1000%

|

Request A quick Quote (WhatsApp:+ 86-18792456795)

tel

tel